We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Spring Clips

Spring Clips

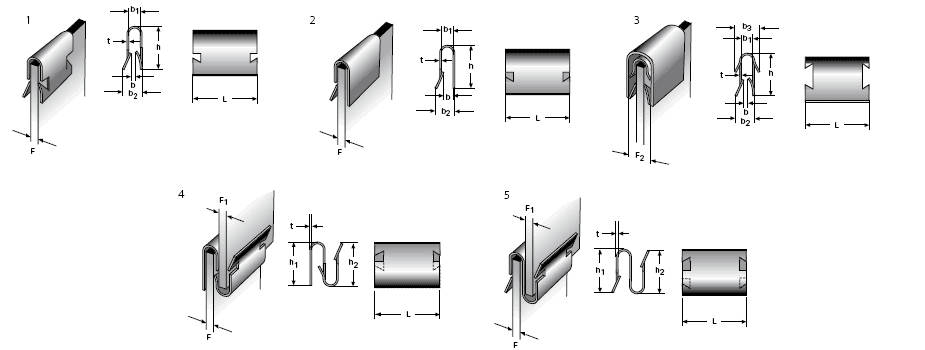

At Metrol Motion Control, we are expert spring clip manufacturers who can create these crucial components in various specifications to suit any application.

If you'd like to learn more before you buy your spring clips, download our complete spring and wire form catalogue to learn more about the range of specifications we supply. Each specification of the steel spring clip comes with a downloadable CAD file that can provide you with essential data to assist your machine design process.

What are Spring Clips?

Spring clips are fasteners slotted between two moving parts of a machine. Additionally, depending on your design, they can be snapped around a part of your machine to hold it in place. For example, a roller pin is curved at the middle point and will snap around the roller's waist while holding the roller in place on the head.

Clips are used to replace any bolt, nut and washer combinations that are commonly used to attach machine components. Spring clips are often used in retaining and clamping applications such as assembling drive shafts. This is due to the superior grip that empowers them to resist movement and tension. They are also effective for reducing the effect of vibrations amongst machine components.

UK Spring Clip Suppliers

We've got all you need for your next project. You can choose any order size from small to large, and with our advanced manufacturing methods, you can be confident in the quality of your components. It should be noted, however, that variations in finish can occur, and the illustrations above show the basic design and slight deviations may occur.

If you'd like any technical support before ordering with us, please call us on 01604 499332 during office hours. Alternatively, you can use our enquiry form, and a company representative will reply within 48 hours. For any enquires from Northern Ireland or the Republic of Ireland, please email us at [email protected]

Spring Clip Material:

Spring steel CK 67

Spring Clip Finish:

Bright zinc (FZB)

Galvanised + yellow chrome (FZG)

Galvanised + black chrome (FZS)

Phosphate and oiled (Fosf.)

Normal finish, according to the table. Variations in finish can occur and is Hardened to 390–540 Vickers.

The illustrations above show the basic design, although slight deviations may occur.