We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Spire Clips

Spire Clips

Metrol Motion Control supplies a broad range of spring nuts and spire clips for industrial uses such as machine design, building installation and many other applications. Spire clips and speed clips are essential to securing various installed elements and are most commonly found in automotive applications.

Chimney Nuts

Chimney nuts are highly adaptable and used in many different applications. These nuts are easily identified by their deep threat form fastener. In addition, the inbuilt multiple-thread form provides a stronger fixing than alternative spring steel U nuts, which employ self-tapping screws with only a single thread engaged. Compared to U clip nuts, the benefit of multiple threads is clear. They can provide greater torque for the clamp load and maintain a more robust and secure joint.

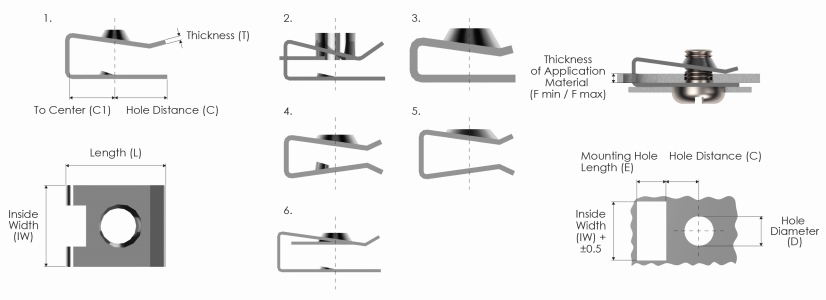

You can download our complete spring and wire form catalogue to learn more about the range of specifications we supply. Each specification of steel spring clip comes with a downloadable CAD file that can supply you with essential data to assist your machine design process. It should be noted, however, that variations in finish can occur, and the illustrations above show the basic design, and slight deviations may occur.

We've got all you need for your next project. If you'd like any technical support before you order with us, feel free to call us on 01604 499332 during office hours. Alternatively, you can use our enquiry form, and a company representative will reply within 48 hours. For any enquires from Northern Ireland or the Republic of Ireland, please email us at [email protected]

Material:

Spring steel CK67

Finish:

Bright zinc (FZB)

Galvanised + yellow chrome (FZG)

Galvanised + black chrome (FZS)

Phosphate and oiled (Fosf.)

Standard finish as per table. Variations in finish can occur.

Hardened to 390–540 Vickers

The illustrations above show the basic design, although slight deviations may occur.