We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Fixed Force Gas Struts

Metrol Springs manufacture a broad range of high-quality premium fixed force gas struts.

Fixed force gas struts have the force preset when they're manufactured so that on delivery, they can quickly be installed into your application. Therefore, fixed force gas springs are ideal for use when the force required is known.

Fixed force gas struts are practical for volume applications, where it's perfect to have the fixed force gas strut fitted without the requirement to adjust the pressure for each one.

Take a look through our selection below, or consider downloading our complete online catalogue of fixed force gas struts. We have everything from 4mm rods up to 20mm.

Please choose a gas strut range below. Smaller diameters deliver lower force, while larger diameters can generate forces of several thousand Newtons.

-

NS-FF-4-20 Fixed Force Gas Strut

NS-FF-4-20 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 20mm

- Extended Length: 72mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

- Force Progression: 27%

Price Range:

P.O.A -

NS-FF-4-30 Fixed Force Gas Strut

NS-FF-4-30 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 30mm

- Extended Length: 92mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-40 Fixed Force Gas Strut

NS-FF-4-40 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 40mm

- Extended Length: 112mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-50 Fixed Force Gas Strut

NS-FF-4-50 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 50mm

- Extended Length: 132mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-60 Fixed Force Gas Strut

NS-FF-4-60 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 60mm

- Extended Length: 152mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-70 Fixed Force Gas Strut

NS-FF-4-70 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 70mm

- Extended Length: 172mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-80 Fixed Force Gas Strut

NS-FF-4-80 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 80mm

- Extended Length: 192mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-4-100 Fixed Force Gas Strut

NS-FF-4-100 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 100mm

- Extended Length: 232mm

- Rod Diameter: 4mm

- Body Diameter: 12mm

- Force Range: 10 - 140N

Price Range:

P.O.A -

NS-FF-6-40 Fixed Force Gas Strut

NS-FF-6-40 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 40mm

- Extended Length: 115mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£13.86 - £19.80 -

NS-FF-6-60 Fixed Force Gas Strut

NS-FF-6-60 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 60mm

- Extended Length: 155mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£14.09 - £20.12 -

NS-FF-6-80 Fixed Force Gas Strut

NS-FF-6-80 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 80mm

- Extended Length: 195mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£14.16 - £20.24 -

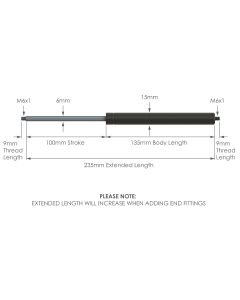

NS-FF-6-100 Fixed Force Gas Strut

NS-FF-6-100 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 100mm

- Extended Length: 235mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£14.33 - £20.47 -

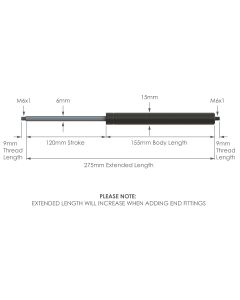

NS-FF-6-120 Fixed Force Gas Strut

NS-FF-6-120 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 120mm

- Extended Length: 275mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£14.46 - £20.65 -

NS-FF-6-150 Fixed Force Gas Strut

NS-FF-6-150 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 150mm

- Extended Length: 335mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£14.58 - £20.81 -

NS-FF-6-200 Fixed Force Gas Strut

NS-FF-6-200 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 200mm

- Extended Length: 435mm

- Rod Diameter: 6mm

- Body Diameter: 15mm

- Force Range: 30 - 400N

- Force Progression: 27%

Price Range:

£15.51 - £21.16 -

NS-FF-8-60 Fixed Force Gas Strut

NS-FF-8-60 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 60mm

- Extended Length: 165mm

- Rod Diameter: 8mm

- Body Diameter: 18mm

- Force Range: 50 - 650N

- Force Progression: 33%

Price Range:

£15.05 - £21.49 -

NS-FF-8-80 Fixed Force Gas Strut

NS-FF-8-80 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 80mm

- Extended Length: 205mm

- Rod Diameter: 8mm

- Body Diameter: 18mm

- Force Range: 50 - 650N

- Force Progression: 33%

Price Range:

£15.12 - £21.60 -

NS-FF-8-100 Fixed Force Gas Strut

NS-FF-8-100 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 100mm

- Extended Length: 245mm

- Rod Diameter: 8mm

- Body Diameter: 18mm

- Force Range: 50 - 650N

- Force Progression: 33%

Price Range:

£15.20 - £21.70 -

NS-FF-8-120 Fixed Force Gas Strut

NS-FF-8-120 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 120mm

- Extended Length: 285mm

- Rod Diameter: 8mm

- Body Diameter: 18mm

- Force Range: 50 - 650N

- Force Progression: 33%

Price Range:

£15.31 - £21.86 -

NS-FF-8-140 Fixed Force Gas Strut

NS-FF-8-140 Fixed Force Gas StrutSPECIFICATIONS AVAILABLE

- Stroke: 140mm

- Extended Length: 325mm

- Rod Diameter: 8mm

- Body Diameter: 18mm

- Force Range: 50 - 650N

- Force Progression: 33%

Price Range:

£15.42 - £22.02

Technical Specifications:

- Rod diameter ranges from 4mm – 14mm

- Body diameter ranges from 12mm – 27mm

- Stroke ranges 20mm – 500mm

- Compressed length = 100mm. Compressed length in a fixed force gas strut is when the rod is compressed into the cylinder and not in a relaxed state.

- Extended length ranges 72mm – 1055mm. Extended length in a fixed force gas strut is when the rod is in its relaxed state and fully extended.

- Panel wight ranges from 1kg – 350kg

- Force progression = 27%, 33%, 39%, 52%

- Threads = M4x0.7x4mm, M6x1x9mm, M8x1.25x9mm, M10x1.5x11mm

- Force ranges 10N – 2500N

Materials available:

Fixed Force Gas Struts are available in mild steel and 316 stainless steel.

Working temperature range:

The working temperature range is -30°c to +80°c.

Certifications & Standards:

Our Fixed Force Gas Struts conform to PED 2014/68/EU. Explore our full list of certifications and standards.

Applications & Industries:

Our fixed force gas struts can be used in various industries such as industrial machinery, marine, agricultural, automotive, medical, automation, manufacturing, plant and machinery and more!

These gas struts can be used in lifting, aiding controlled movement, supporting or adjusting the position of an object, dampening movement, counterbalancing for raising, lowering movements, and more.

Gas strut installation:

Please see our full guide on how to install your gas strut:

- Ball joints are used to ensure any side loading will be alleviated and uneven wear on the seals doesn’t occur.

- When installing the strut, it should always be in its relaxed state and the piston facing downwards, to ensure the guide and sealing systems are lubricated.

- To prolong lifespan, keep the strut in one plane of movement.

- The end fittings need to be securely fastened to the thread of the strut before installation.

If you are fitting your strut to a bracket, please follow these basic steps. Check out our detailed guide for more complex installations.

- If you are fixing the end fitting to a bracket, you should first undo the retaining clip from the ball socket.

- Once you have done this, check that the ball socket is firmly tightened to the struts thread and remove the ball stud from the socket.

- You should then place the ball socket over the bracket and click it into place.

- Finally, connect the retaining clip back into the two locating holes and clip it over the collar again.

To promote safety, your gas strut should only ever be installed in its relaxed state.

Guarantee:

Metrol offer a 2 year guarantee under normal usage.

FAQ’s:

What is the difference between fixed-force and adjustable gas struts?

A fixed force gas strut is pre-charged to an exact force and this cannot be changed in the field. An adjustable force gas strut has a pressure release valve, and it is charged to the top of the force range. You can then use the Allen key provided to let out some of the pressure, therefore lowering the force.

Can I adjust the force of a fixed-force strut?

No, fixed force gas struts are ideal for when you know the exact force required and want a quick installation.

How do I determine the correct force rating for my application?

The best way to determine the correct force rating is by using our free online design service.

Another method is to weigh the application and use the calculation that approximately 10kg requires 100 newtons of force.

The final way is to buy a variable gas strut, install it on your application and adjust the pressure. You can then send it back to us, and we will measure the force and provide the correct fixed force gas struts.

Are fixed-force gas struts suitable for high-temperature environments?

Fixed force gas struts are suitable for temperatures ranging from -30°c to +80°c.

What maintenance is required to extend the lifespan of a fixed-force strut?

None. Standard practice to maintain the longevity of the strut would be to keep the rod down in its resting state, and never use 100% of the stroke. Dust covers or protection tubes are also available to help prevent damage.

How do I install fixed force gas struts?

Please see our installation guide for more information.

What other gas struts can I order from Metrol?

We have a wide range of gas struts available including adjustable force gas struts, traction gas struts, gas struts for bed brackets, pin locking gas struts, mechanical locking gas struts and stainless steel gas struts. We also offer gas strut end fittings and accessories.

What are the advantages of fixed force gas struts?

The main advantage of using fixed force gas struts is easy installation due to them being pre-charged at the correct force for your application. This is a major advantage if you are installing a large volume of gas struts as it will save a lot of time.

End fittings:

When buying end fittings, a drop-down selection will be on the product page with all of the compatible fittings for your selected strut. You can then select the rod and body end fittings you require and also any extra accessories and brackets. You will also be asked to select the force that you require, with the option to input a custom force.

High-Quality Custom Fixed Force Gas Struts

We've got all you need for your next project. If you'd like any technical support before you order with us, feel free to call or WhatsApp us on 01604 499332 during office hours. Alternatively, you can use our enquiry form, and a company representative will reply within 48 hours. For any enquires from Northern Ireland or the Republic of Ireland, please email us at [email protected].