We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Power Springs

Available in stainless steel. Minimum order value of £15+VAT. Shipping to the UK only.

Power Springs

What are Power Springs?

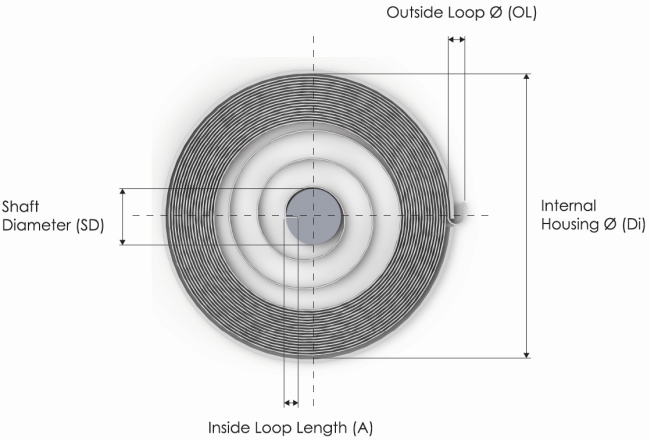

Power springs are manufactured from flat strips of spring-tempered metal tightly wound into a coil. The term power spring is interchangeable with clock springs in the spring industry; however, here at Metrol, we observe a distinction as our power springs are wound tighter with the rotating loops of flat spring material being in contact with each other. This makes them more powerful but requires lubrication.

Common Uses

Our power springs are commonly used in the following applications:

- Medical

- Automotive

- Appliance

- Cord reels

- Cable reels

- Defence

- Elevator door closures

- Fall safety restraints

- Hose reels

- Outdoor power equipment

- Tool balancers

- Window balance systems

- Other specialised retraction and counterbalance systems

Power springs are very versatile and can be seen in almost all industries within various applications. Day to day power spring applications include:

- Car seat belts

- Dog leads

- Tape measures

- Lawnmower starter cables

Power Springs at Metrol

Here at Metrol, our flat spring range includes constant torque springs, clock springs, power springs, and reels. All products can be custom designed and manufactured to each customer's unique performance and size requirements. Please see the flat spring sections of the Metrol springs catalogue download for further details.

We also supply a cross-curved range using thinner material. These achieve the same properties as our original range but are lighter in weight.

Fitting a Power Spring

All power springs should be lubricated when fitted and the coils separated. Without lubrication, the spring force can reduce by up to 20%. In addition, multiple springs can be placed next to each other for increased torque, with a washer used between the springs.

For additional fitment details, please see the power springs catalogue.

Material and Finishings

These springs are supplied with a protective ring or nylon band that you must remove during assembly. The spring should be handled with care and held using a suitable tool while being positioned in the housing.

Stainless steel: EN 10151 1.4310

Nominal torque without effect from friction stated.

1 kp = 9.80665 Newtons, 1 Newton = 0.10197 kp

Contact Our Experienced Team Today

As an experienced spring manufacturer, we can create a whole range of springs perfect for any application within any industry.

If you need help placing an order or have any questions, please don't hesitate to contact us using our online form or call us on 01604 499332. Alongside our standard range, we also provide customised solutions using design capabilities and advanced, proprietary spring design software. We also offer performance testing that allows for rapid production of spring prototypes to help our customers achieve a competitive advantage by improving their speed-to-market. By providing expert metallurgical knowledge with long experience in spring production, we have the expertise to optimise spring design.