We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Die Springs

Die Springs

Die springs are manufactured from rectangular wire and are essentially extra high-quality compression springs for use in press tools, valves, couplings, fixtures, and other applications where high loads are required in a confined space.

Advantages of a Die Spring

Die springs are very advantageous, designed specifically to consistently output a given force under compression even when used at high temperatures or even after countless repetitions at high force. Of course, different die springs in the Metrol range have varying load capacities and load cycle limits. For each dimension, there are seven separate force classes to choose from. These can be viewed in our wire springs catalogue. All our springs have a rectangular profile which allows for a shorter solid length. This increased deflection capacity makes them suitable for an wider range of applications.

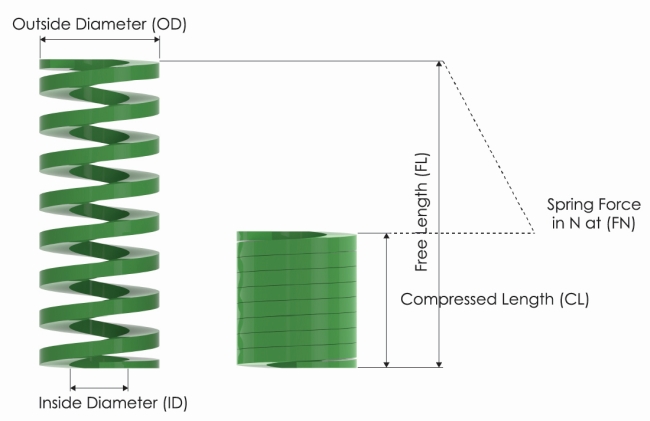

Legend:

R = Spring Rate

F3 = Spring force in Newtons at s3

s3 = Spring deflection at F3

Material:

EN 10089 and EN10270-2

Finish:

Epoxy varnish

Max. working temperature: 200 °C

1 kp = 9.80665 Newtons, 1 Newton = 0.10197 kp

In order to achieve the best characteristics and lifecycle, we follow a well-developed production process.

- A special alloy has been developed, giving improved heat resistance and less relaxation. The closest comparable material is EN 10089 and EN10270-2.

- Extremely low surface decarburisation free from surface defects.

- The rectangular profile allows a shorter solid length, thereby increasing deflection capacity.

- A higher permitted level of stress affords a considerably longer lifespan.

- Close tolerances allow for precise fitting in existing space.

Metrol’s Manufacturing Process

We use a well-developed and highly refined process to manufacture world-leading die springs with excellent characteristics and lifecycle limits. We developed a special alloy to improve heat resistance and exhibit less relaxation. Whilst not the same, a comparable material would be EN 10089 or EN 10270-2 (tempered steels). The special alloy we use has extremely low surface decarburisation, meaning our springs are free from surface defects. We work to precise tolerances to create a range of die springs that are reliable and accurate.

When to Use a Die Spring

Since die springs are very similar to compression springs, except with higher pressure and heat resistance, you may think that choosing die springs over standard compression springs is the natural choice to ensure you use the best spring available. However, whilst die springs are excellent when used in their intended environments, they are bulky and not cost-effective when considered for use in an application suitable for standard compression springs. If you are not sure which type of spring you need, please don’t hesitate to contact one of our wire spring experts by calling +44 (0)1604 499 332. We will be more than happy to offer advice.

Industries that Commonly Need Die Springs

Whilst it may seem uncommon to see a square-coiled spring, die springs are ubiquitous across many industries. For example, they are used widely in the automotive, transport, and agriculture sectors, often where heavy machinery operates under high forces.

Order Your Springs from Metrol

Our die springs are available with free lengths ranging from 20-305mm and inside diameters from 5 to 38mm. If you still don’t see what you need, please don’t hesitate to fill out our custom die springs form. We can custom manufacture springs to your exact requirements.

If you are interested in one of the standard die springs, providing they are in stock, you can order them online to arrive via Next Day or Express delivery (working days only). We use DPD as our domestic courier (to UK postcodes), and we can also offer international shipping if you need the springs sent further afield. Please don’t hesitate to get in touch for more information.