We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Clock Springs

Available in stainless steel. Minimum order value of £15+VAT. Shipping to the UK only.

Clock Springs

What is a Clock Spring

A clock spring gets its name from the motion of movement that the spring exhibits. They are found in watches, but many other objects and industries also utilise them. Unlike wire torsion springs, clock springs are made from flat metal strips. You may find them referred to as a flat torsion spring or a type of flat spring. Clock springs are designed to produce a torsional force in a circular movement. Force applied to a clock spring that coils around itself generates more torsional force as the spring tries to uncoil. Conversely, the more the spring is unwound, the less force is exhibited, in contrast to how a constant torque spring functions.

The term clock spring is commonly interchanged with the following:

- Power spring

- Motor springs

- Mainsprings (watchmaking)

- Hair springs

- Balance springs

Here at Metrol, we observe a distinction between our clock springs and power springs. For the latter, the coils wound tighter, and the rotating spirals of flat spring are in contact with one another. This requires lubrication but allows a greater torsional force within applications.

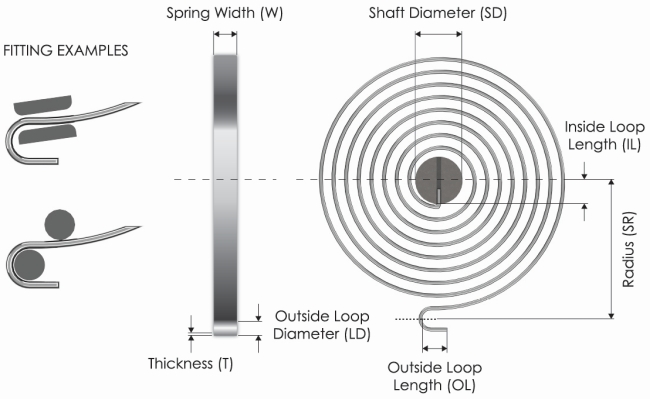

Legend

TC = Total Number of coils

R = Spring Rate, Nmm per degree of torque

Advantages of a Clock Spring

Although similar in appearance to power springs and constant torque springs, unlike tightly coiled power springs, clock springs have open coils with equal distance between. When mounted correctly, this reduces friction to zero. In addition, they do not require lubrication due to the lack of friction between moving parts. However, torque capacity is reduced as a result. Clock springs can be mounted in parallel in an application to provide a greater torsional force if required. They are also a cost-effective option when needing a torsional spring.

Metrol’s Clock Springs

Here at Metrol, our clock spring standard range is manufactured from rounded edge stainless steel. This affords a better fatigue life than many other materials used to make these springs in the industry.

Common Uses

Clock springs are commonly used in steering mechanisms, allowing the wheel to turn while still connected to various electrical systems. Most devices that require a smooth retraction system will operate with the assistance of a clock spring. Mechanical timers, lanyards and wind-up toys are just a few examples of products that function using clock springs.

Fitting Your Clock Springs

We recommend the clock spring be assembled on a grooved shaft with a milled or rounded end. To prevent the spring from forming an eccentric shape, compromising torque force and spring life, the outer end should be fixed as shown in the clock springs section of our springs catalogue. You will also find information about permitted static load and torque angles in this catalogue. If you need further assistance about permitted torques or anything to do with assembly, please call us on 01604 499332.

Order Online Today

You can receive spring products, providing they are in stock at the time of purchasing, the very next day with either Next Day or Express Delivery. Please note, this only applies to working days. You can find more information about UK shipping and international shipping with our DPD courier on our website.

As an experienced clock spring manufacturer, we’re here to offer guidance on our products’ optimum use or application. If you need any help, feel free to contact us using our online form.