We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Single Torsion Springs

Available in stainless steel. Minimum order value of £15+VAT. Shipping to the UK only.

Single Torsion Springs

Our high-quality cylindrical wound torsion springs can be used for axial loads, i.e. a circular movement. When loaded, the wire is exposed to a deflection, and normally, the inside body diameter is mounted on a shaft or similar.

Our single torsion springs must be mounted in such a way that there is always play between the inner diameter and the shaft.

The load must be applied so that the torque application binds the spring, as it is strongest in this direction. To minimise the friction against the shaft, we would always recommend using fixed tension ends.

These springs have a linear spring characteristic. For example, if the spring is turned 10° to provide a torque of 1 Nmm, the same spring will provide a torque of 2 Nmm at 20° torsion.

Contact Our Experienced Team Today

As torsion spring manufacturers, we can advise you on the use and application of our products. If you need help, please don’t hesitate to contact us using our online form or directly by calling us on 01604 499332.

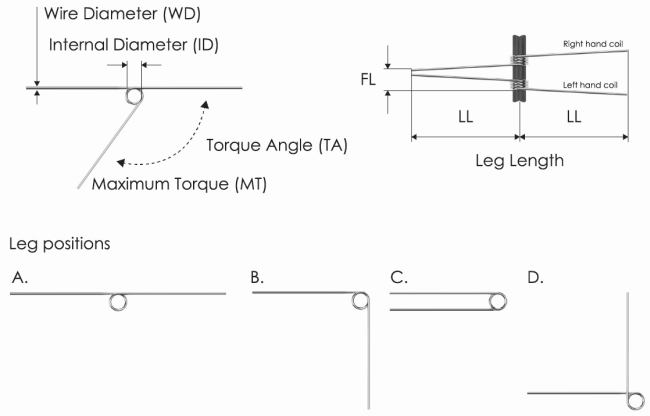

Legend:

TC = Number of sprung coils

R = Spring Rate, Nmm per degree

Torque:

Torque is equal to force x leg length: MT= F x LL.

The closer to the end of the leg the load is applied, the less counter force is created. The following tables specify torque in Nmm, i . e . the force obtained on the leg 1 mm from the centre.

Permitted load, life:

If the maximum torque angle (TA) is used, a maximum of 10 000 load cycles is permitted. If only 80% of the permitted torque angle is used, the lifespan of the spring increases to 200 000–400 000 load oscillations. If only 70% of the permitted torque angle is being used, an almost infinite lifespan can be expected.

Ends:

The ends in this standard stock catalogue are produced to a basic design, i.e. straight.

Material:

Stainless steel: EN 10270-3-1.4310

1 kp = 9.80665 Newtons, 1 Newton = 0.10197 kp