We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

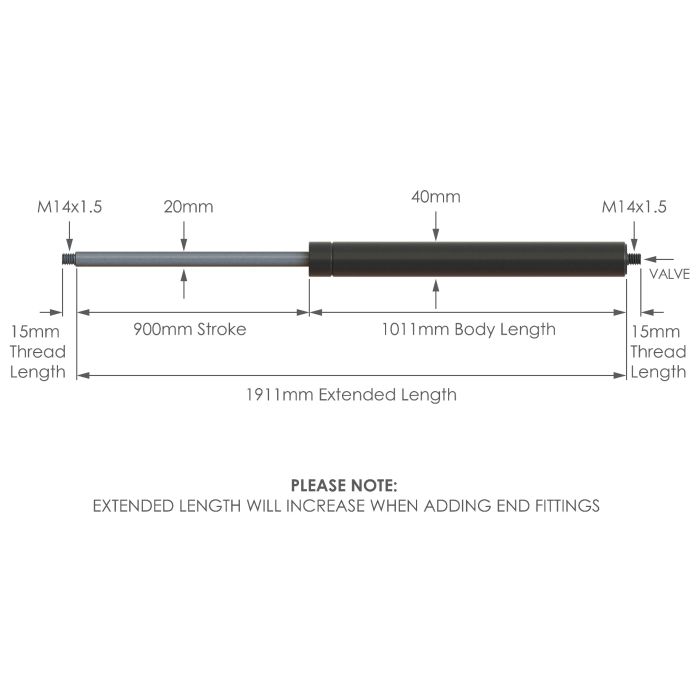

NS-V-20-900 Variable Force Gas Strut

SKU

NS-V-20-900

| Stroke | 900mm |

|---|---|

| Extended Length | 1911mm |

| Rod Diameter | 20mm |

| Body Diameter | 40mm |

| Force Range | 300 - 5000N |

| Force Progression | 45% |

£324.81

All prices exclude VAT

VOLUME DISCOUNTS

- QUANTITYPRICE

- 6 + £308.58

- 20 + £259.85

- 50 + £227.38

-

Product codeProduct DescriptionStock Status

-

NS-V-20-900NS-V-20-900 Variable Force Gas Strut

-

B16Ball Joint End Fitting with 14mm Thread B16

-

E14Eye End Fitting with 14mm Thread E14

-

C4Clevis Fork with 14mm Thread C4

-

RE16Rose Eye End Fitting with 14mm Thread

-

C4-CLIPC4CLIP 14mm Clevis Fork Clip