We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

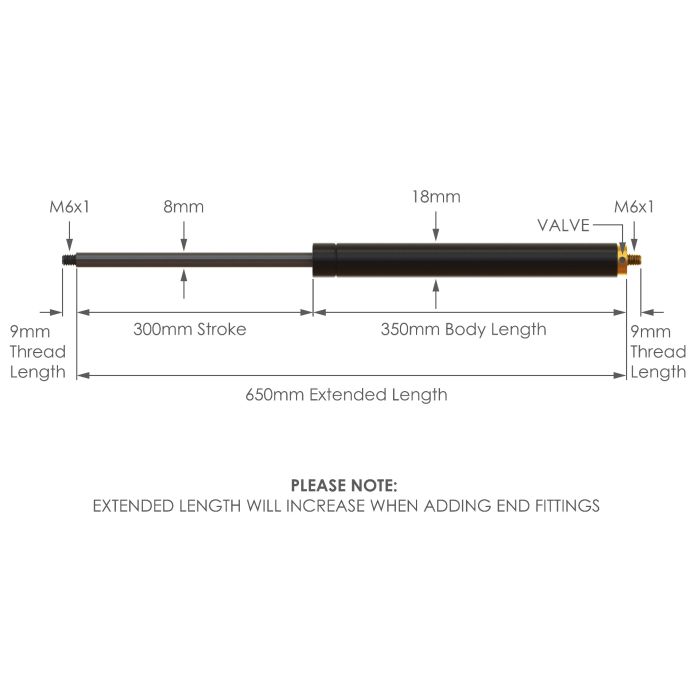

NS-V-8-300 Variable Force Gas Strut

SKU

NS-V-8-300

| Stroke | 300mm |

|---|---|

| Extended Length | 650mm |

| Rod Diameter | 8mm |

| Body Diameter | 18mm |

| Force Range | 50 - 650N |

| Force Progression | 33% |

£26.59

All prices exclude VAT

VOLUME DISCOUNTS

- QUANTITYPRICE

- 6 + £25.26

- 20 + £21.28

- 50 + £18.62

-

Product codeProduct DescriptionStock Status

-

NS-V-8-300NS-V-8-300 Variable Force Gas Strut

-

B0-ABall Joint End Fittings with 6mm Thread full range-M5-18.50mm-8mm

-

B0Ball Joint End Fitting with 6mm Thread Full Range-M5-22mm-8

-

B1Ball Joint End Fitting with 6mm Thread Full Range-M6-18mm-10

-

B2Ball Joint End Fitting with 6mm Thread Full Range-M6-20mm-10

-

B3Ball Joint End Fitting with 6mm Thread Full Range-M6-25mm-10

-

B4Ball Joint End Fitting with 6mm Thread Full Range-M6-30mm-10

-

B5Ball Joint End Fitting with 6mm Thread Full Range-M8-18mm-10

-

B6Ball Joint End Fitting with 6mm Thread Full Range-M8-20mm-10

-

B7Ball Joint End Fitting with 6mm Thread Full Range-M8-25mm-10

-

B8Ball Joint End Fitting with 6mm Thread Full Range-M8-30mm-10

-

PB0Plastic Ball Joint End Fittings with 6mm Thread full range-M5-18mm-8mm

-

PB1Plastic Ball Joint End Fittings with 6mm Thread full range-M6-18mm-10mm

-

PB2Plastic Ball Joint End Fittings with 6mm Thread full range-M6-25mm-10mm

-

PB3Plastic Ball Joint End Fittings with 6mm Thread full range-M8-18mm-10mm

-

PB4Plastic Ball Joint End Fittings with 6mm Thread full range-M8-25mm-10mmChat or Contact us

-

E0Eye End Fitting with 6mm Thread full range-6mm-17mm

-

E1Eye End Fitting with 6mm Thread full range-8.5mm-18mm

-

E2Eye End Fitting with 6mm Thread full range-8.5mm-20mm

-

E3Eye End Fitting with 6mm Thread full range-8.5mm-22mm

-

E4Eye End Fitting with 6mm Thread full range-8.5mm-25mm

-

E5Eye End Fitting with 6mm Thread full range-8.5mm-30mm

-

CE2Shoulderless Eye End Fitting with 6mm Thread-8.25mm-16mm

-

CE5Shoulderless Eye End Fitting with 6mm Thread-8.25mm-20mm

-

C1Clevis Fork with 6mm Thread C1

-

RE8Rose Eye End Fitting with 6mm Thread

-

BRK-1BRK-1 10mm Right Angle Bracket with 32mm Fixing Centres

-

BRK-2BRK-2 10mm Circular Bracket with 20mm Fixing Centres

-

BRK-3BRK-3 10mm Triangular Bracket with 22.5mm Fixing Centres

-

BRK-4BRK-4 10mm Circular Bracket with 41mm Fixing Centres

-

BRK-5BRK-5 10mm Right Angle Bracket with 26mm Fixing Centres

-

BRK-052-LBRK-052-L 10mm Internal Right Angle Bracket with 50.6mm Fixing Centres

-

BRK-052-RBRK-052-R 10mm External Right Angle Bracket with 50.6mm Fixing Centres

-

BRK-6BRK-6 10mm Internal Right Angle Bracket with 38mm Fixing Centres

-

BRK-6RBRK-6R 10mm External Right Angle Bracket with 38mm Fixing Centres

-

BRK-7BRK-7 10mm Triangular Bracket with 55mm Fixing Centres

-

BRK-10BRK-10 10mm Triangular Bracket with 32mm Fixing Centres

-

BRK-4BBRK-4B 8mm Circular Bracket with 41mm Fixing Centres

-

BRK-7BBRK-7B 8mm Triangular Bracket with 55mm Fixing Centres

-

BRK-8BRK-8 8mm U Shaped Bracket with 50mm Fixing Centres

-

BRK-8-90BRK-8-90 8mm U Shaped Bracket with 51mm Fixing Centres

-

BRK-12BRK-12 10mm Right Angle Bracket with 55mm Fixing Centres

-

BRK-12-NBBRK-12-NB 8mm Eye Right Angle Bracket with 55mm Fixing Centres

-

BRK-12RBRK-12R 10mm Right Angle Bracket with 55mm Fixing Centres

-

C1CLIPC1CLIP 6mm Clevis Fork Clip

-

DC-SD028mm Rod Dust Cover for 18mm Body Gas Struts

-

PPT-8-3008mm Plastic Protection Tube-300mm