We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

NS-SS-V-14-400 Stainless Steel 316 Variable Force Gas Strut

SKU

NS-SS-V-14-400

| Strut Force Type | Adjustable Force |

|---|---|

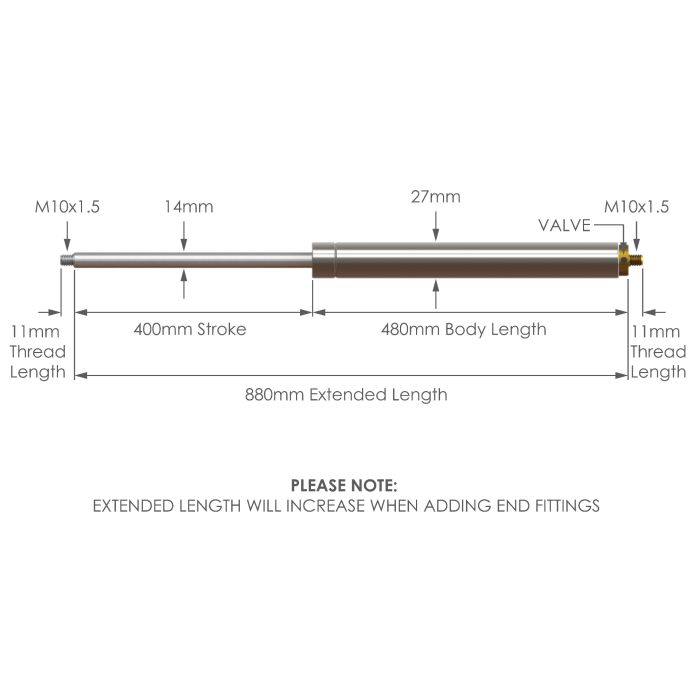

| Stroke | 400mm |

| Extended Length | 880mm |

| Rod Diameter | 14mm |

| Body Diameter | 27mm |

| Force Range | 150 - 2500N |

| Force Progression | 52% |

£117.37

All prices exclude VAT

VOLUME DISCOUNTS

- QUANTITYPRICE

- 6 + £111.49

- 20 + £93.90

- 50 + £82.15

-

Product codeProduct DescriptionStock Status

-

NS-SS-V-14-400NS-SS-V-14-400 Stainless Steel 316 Variable Force Gas Strut

-

SSB15Stainless Steel 316 Ball Joint End Fitting with 10mm Thread

-

SSE13Stainless Steel 316 Eye End Fitting with 10mm Thread SSE13

-

SSC3Stainless Steel 316 Clevis Fork with 10mm Thread

-

SSBRK-8SSBRK-8 Stainless Steel 304 8mm U Shaped Bracket with 50mm Fixing Centres

-

SSBRK-8-90SSBRK-8-90 Stainless Steel 316 8mm U Shaped Bracket with 51mm Fixing Centres

-

DC-SD04-BLK14mm Rod Dust Cover for 27mm Body Gas Struts